How do you know your backup power source will provide the energy you need to keep operations running when the power goes out?

Most mission-critical industries use standby power sources like UPS and generators to provide continuous power to their facilities during power outages. Load banks allow you to test your power sources whenever you need to ensure reliable power when you need it most.

Choosing the right load bank is critical for accurate power source testing. To help you find the best load bank for your facility’s needs, this guide discusses the various types of load banks available to you, common applications for each type and the benefits of renting a load bank.

What Types of Load Banks Are There?

Six types of load banks are commercially available. Each type has different capabilities that allow you to conduct multiple types of tests. They also come in many different sizes and configurations to meet specific power needs. Custom load banks are also available if a commercial type doesn’t meet your needs.

1. Resistive Load Banks

Resistive load banks are the most commonly used type of load bank. They work by drawing a real specified power load from an attached power supply and converting that energy into heat.

By using a resistive load bank, you can test general-purpose power sources to determine whether they are fit to handle typical loads. This testing process also confirms that a power source’s cooling, engine and exhaust systems function properly.

Most resistive load banks contain internal cooling systems, but some models rely on airflows from external sources like generators to maintain safe temperatures.

Common applications for resistive load banks include:

- Full load testing: Resistive load banks can apply a load up to 100% at a power factor of 1.0, which allows you to test a power source’s ability to respond under a full load.

- Wet stacking prevention: Many diesel generators only operate at loads of 50% or lower, which can quickly lead to wet stacking. Using a resistive load bank, you can apply a higher-than-typical load to the generator, which can burn off the buildup in the engine.

- Performance optimization: You can optimize performance by supplementing the actual load on the power source. This can prevent or clear wet stacking and properly treat exhaust fumes, keeping the power source’s internal systems clear.

2. Reactive Load Banks

Because reactive load banks can simulate loads that resemble typical operating conditions, they’re the most suitable load bank type for critical facility commissioning tests.

Unlike resistive load banks, reactive load banks can test power sources for full apparent power in kilovolt-amperes (kVA). This makes them an especially effective bank for testing emergency standby generators in mission-critical operations. Additionally, unless the manufacturer tested its capabilities before release, you will need to test power sources upon installation to ensure that they operate at full nameplate kVA rating.

Reactive load banks create a lagging power factor of 0.8 with a 75% load, which leads to voltage drops in the tested power source. This property allows you to test your power sources for sensitivity to voltage dips.

3. Resistive-Reactive Load Banks

Resistive-reactive load banks combine the properties of both resistive and reactive models, enabling them to supply power sources with both load types. This hybrid capability allows them to create loads that closely resemble typical use conditions, enabling a more thorough performance test for UPS and generator systems.

Depending on unit size, resistive-reactive load bank capacities can range from 300 to 1,875 kVA at a power factor of 0.8. At that same power factor, their load capacity ranges from 240 to 1,500 kW.

4. Inductive Load Banks

Inductive load banks contain cores of either iron or air, which create a lagging power factor load. Because induction load banks resist current changes, the current lags the voltage. These loads usually have a power rating of 75% of the corresponding resistive load, which produces a power factor of 0.8.

Inductive load banks are often used with resistive load banks to test an entire system effectively.

These units have two types of power:

- Real: The work done by the test device creates real power, such as the energy provided by a spinning motor.

- Reactive: Inductive load banks create magnetic fields through reactive power.

The total power a load bank consumes is a combination of both types of power and is measured using volts-amps-reactive (VAR).

5. Capacitive Load Banks

In contrast to inductive load banks, the voltage lags the current in capacitive load banks. The reactive power of capacitive loads is opposite in polarity to that of an inductive load, which is why they have negative VAR values.

Capacitive load banks are less common than resistive or resistive-inductive banks. Because they’re better at simulating electric and non-linear loads specific to computer and telecommunications systems, they’re frequently used for commissioning mission-critical power systems in facilities like hospitals and data centers. You can also use capacitive load banks to periodically monitor generator and UPS performance to ensure your power source can handle emergency usage.

6. Electronic Load Banks

Electronic load banks are highly programmable devices that allow you to determine a power source’s average and maximum load capacities. It works by applying an electrical load to the test power source, which delivers a precise reading. This electrical load can be either AC or DC depending on the intended test.

Generally, electronic load banks come at higher prices than other models, but their precision and programming capabilities provide reliable results in many different settings. You can also use them with external components like automatic testing equipment (ATE) to run a range of tests not usually achievable using traditional load banks.

In addition to testing power source functions, some common applications of electronic load banks include:

- Fuel cell testing

- Design verification

- Device troubleshooting

- Testing multiple unit production

- Testing telecommunications components

7. Custom Load Banks

If a standard load bank is insufficient for meeting your facility’s specific needs, consider implementing a custom solution.

What Size Load Bank Do You Need?

You want to ensure that the load bank you choose can handle the tests you wish to perform without exceeding your needs by too much. However, without solid regulations defining the required load bank sizing for various applications, choosing the right unit for your needs can be challenging.

In general, you’ll want to choose a load bank with a capacity equal to or greater than your power source’s rated output. Using a unit with this capacity allows you to test power sources at or near typical operating conditions — this way, you’ll know for certain whether your power source can handle emergencies.

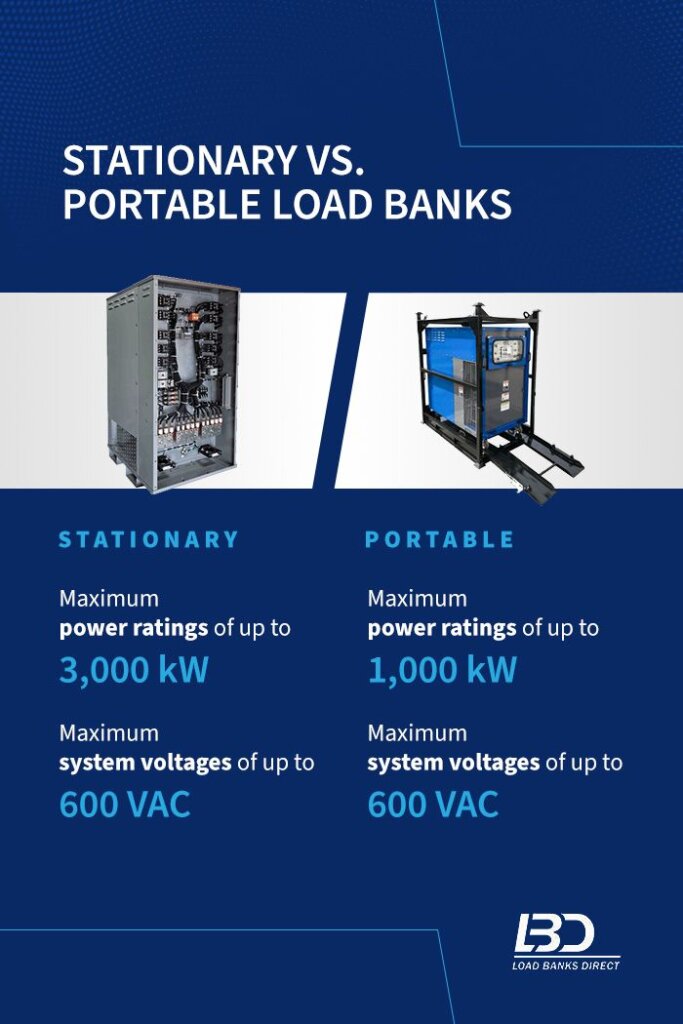

Stationary vs. Portable Load Banks

The load bank testing option you choose should match your application. For example, suppose you frequently need to test large generators in a facility like a hospital or a hotel. In that case, a stationary load bank will allow you to conduct regular tests to monitor the power source’s condition over time, which also helps make preventative maintenance much easier.

On the other hand, a facility that uses many different power sources operating at lower output levels would benefit more from a portable load bank, which can be easily moved between areas. Both types have other advantages and disadvantages depending on each use case.

Stationary Load Banks

Stationary load banks are larger units built into a structure. Generally, they have maximum power ratings of up to 3,000 kW and maximum system voltages of up to 600 voltage in alternating current (VAC). These large units require significantly more space than portable load banks.

For this reason, they’re best suited to facilities requiring frequent testing or load supplementation. They’re also suitable for larger systems connecting to multiple power sources. In these applications, components like busways, breakers and cam-type connector panels are useful for facilitating connections between each standby power source and the load bank.

One example of a stationary load bank is a roof- or duct-mounted bank, which mounts directly on a power source or in the duct and often relies on the power source for cooling airflow. They typically handle maximum loads of 400 to 1,000 kW and are ideal for providing supplemental energy and preventing wet stacking in diesel generators.

Portable Load Banks

Portable load banks are compact load banks that you can move from one test site to the next. Portable load banks can handle maximum loads of up to 1,000 kW and system voltages up to 600 VAC, making them suitable for applications requiring lower power levels.

These units are generally lightweight, with the smallest models weighing just 70 pounds. Models vary in size depending on maximum load and application, but all are highly portable, providing incredible flexibility.

They also come in various configurations for specific applications. For example, rack-mounted load banks — also called server rack heaters — are specifically designed for use in data centers. These load banks mount directly to data center racks and are often used during data center commissioning to ensure that the facility’s heat and cooling systems perform as needed before introducing any computers into the center.

A trailer-mounted load bank is a larger portable load bank that works well for facilities that use remote load banking for on-site generators. Trailer-mounted load banks have greater testing capacities than other portable models with power ratings of up to 3,000 kW — similar to high-capacity stationary models. You can easily transport them between test sites using a truck, and low-profile models are available for applications where space is limited.

What Is Remote Load Banking?

A particularly promising trend in load testing is remote load testing, which has revolutionized the testing process by creating a more precise means of obtaining accurate results than previously possible with manual load banks.

Remote load banking lets you control multiple networked load banks simultaneously from one mobile interface. This connectivity provides incredible flexibility, allowing you to conduct broad system-wide tests or home in on specific parts of the network to pinpoint weaknesses.

What Are the Benefits of Remote Load Banking?

Remote load banking is incredibly advantageous for complex systems involving multiple power sources, such as data centers and large hospitals.

Some of the benefits of remote load banking include the following:

- Reduces costs: Traditional methods of testing a complex system require many technicians working on-site at the same time. Remote testing eliminates the need to activate each load sequence manually during testing, which means you can hire fewer technicians.

- Saves time: Remotely testing multiple power sources means you don’t have to move from source to source to conduct a test — you can use the digital interface to collect data from sources throughout your facility from one location.

- Improves ROI: Decreased labor costs and testing time mean you recoup your investment costs much faster than you would with traditional technology.

- Increases flexibility: Advanced remote control systems provide extra testing capabilities for IT systems such as fault diagnostics, automatic voltage correction and load servo mode, among others.

Should You Rent a Load Bank?

For many organizations, renting a load bank is a convenient, cost-effective alternative to purchasing a new unit.

Considering the following factors can help you determine whether renting is right for your facility:

- Testing frequency: All facilities must conduct load bank testing during the commissioning process, but mission-critical industries such as hospitals and call centers must conduct load tests more frequently than others. Organizations that only need to test occasionally may want to rent a load bank.

- In-house resources: Companies lacking the proper expertise and tools to perform load bank testing can benefit from a load bank rental. Many suppliers provide expert support to help customers get the most out of their rentals.

- Available space: When you purchase a load bank, you need to ensure you have enough room for it even when your facility’s needs change. You’ll also have to find a place to store it when not in use, which can take up valuable space in your facility or increase your storage costs if you rent storage space.

- Evolving needs: If you need to conduct multiple kinds of tests or if your facility’s testing requirements change, renting different types of load banks as you need them can save you money and hassle.

Find the Right Load Bank Type for Your Needs

If you’re looking for an effective testing solution for your facility, Load Banks Direct can help you determine what type of load bank you need. Whether your application calls for a stationary resistive load bank, an elaborate remote testing network or a tailored solution, you can count on us to provide products for accurate, reliable power source testing.

As leading experts in the field, we design and manufacture various portable and stationary load banks, so you have diverse load testing options to choose from. We use the highest quality components to ensure long-lasting products for hospitals, laboratories, data centers and more. We also provide personalized support and extensive online resources to ensure our customers can maximize their investment.

For more information about our load bank solutions, contact us directly or request a free quote using our online forms. We’re here to answer your questions and help you find the best products for your facility.

We Are Here

To Help

Our team is here to support you and solve your power challenges. Connect with our responsive experts today to learn about our customized power solutions and products.